DSI is continually developing new features for EFDC+ and EFDC+ Explorer Modeling System (EEMS). As part of this development process, DSI internally tests the new feature repeatedly to answer the following questions:

- Is the conceptual model scientifically sound?

- Are algorithms properly built to represent the conceptual model?

- Are the computer codes for the new algorithm written correctly?

- Does the new feature effectively reproduce the real phenomena?

In our propeller wash blog series, we have shared details of the propeller wash simulation features that will soon be available in the upcoming version of EEMS. This post introduces a simple testing process to demonstrate how the propeller wash module works with EFDC+‘s sediment transport process modeling features.

Test Model Setup

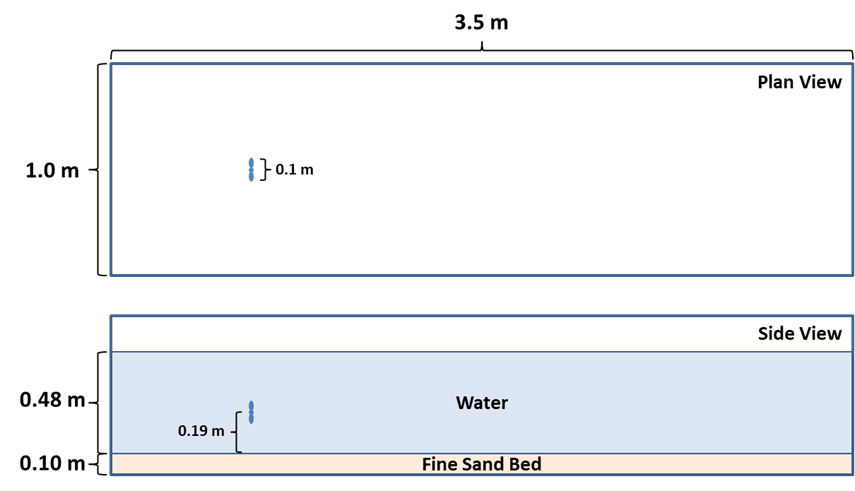

Figure 1 illustrates the dimensions of the synthetic flume used in this demonstration (L 3.5m x W 1m), along with the sediment bed and propeller setup used. The flume has a uniform bottom elevation, and the water depth is 0.48 m. The thickness of the sediment bed is 0.1 m, consisting of fine sand with a constant diameter of 100 µm (non-cohesive particles). The physical and erosional properties of the sediment bed are set to be uniform horizontally and vertically. The four-blade propeller has a diameter of 0.1 m, with a pitch ratio of 1.4, a blade area ratio of 0.4, and a thrust coefficient of 0.51. The propeller shaft was placed 0.19 m above the sediment bed surface. The total simulation period of this demonstration was 30 minutes. The propeller was operating with 1000 rpm for the first 20 minutes during the simulation, and the resuspended particles redeposited to the sediment bed during the 10 minutes remaining after the propeller stopped operating.

Test Features

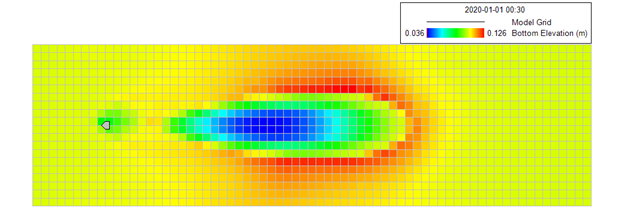

Following the 30-minute model simulation, a shallow hole formed right below the propeller, and the maximum scour occurred about 1 m away from the propeller (Figure 2). The dark colored grids show the areas with lower elevation (hole), and lighter colored grids show the area with higher elevation. The sediments eroded by the propeller from the scour hole deposited around it.

This demonstration also checked the following components to evaluate whether the simulation results were a good representation of the sediment transport process induced by the propeller power.

| Layers | Initial Mass (kg) | Final Mass (kg) |

|---|---|---|

| Bed Layer 12 | 0.00 | 0.00 |

| Bed Layer 11 | 0.00 | 2.04 |

| Bed Layer 10 | 56.68 | 69.28 |

| Bed Layer 9 | 56.68 | 51.92 |

| Bed Layer 8 | 56.68 | 52.86 |

| Bed Layer 7 | 56.68 | 53.95 |

| Bed Layer 6 | 56.68 | 54.54 |

| Bed Layer 5 | 56.68 | 55.41 |

| Bed Layer 4 | 56.68 | 56.79 |

| Bed Layer 3 | 56.68 | 56.68 |

| Bed Layer 2 | 56.68 | 56.68 |

| Bed Layer 1 | 56.68 | 56.68 |

| Total | 566.83 | 566.83 |

-

Sediment Mass Balance: Table 1 compares sediment mass in each sediment bed layer between the beginning and end of the simulation (numbered with Bed Layer 12 as the uppermost layer and Bed Layer 1 as the deepest). The table does not show sediment mass in water layers here because no suspended sediment remained in the water column at the end of the simulation. This comparison indicates that the total sediment mass within the system is conserved during the simulation.

-

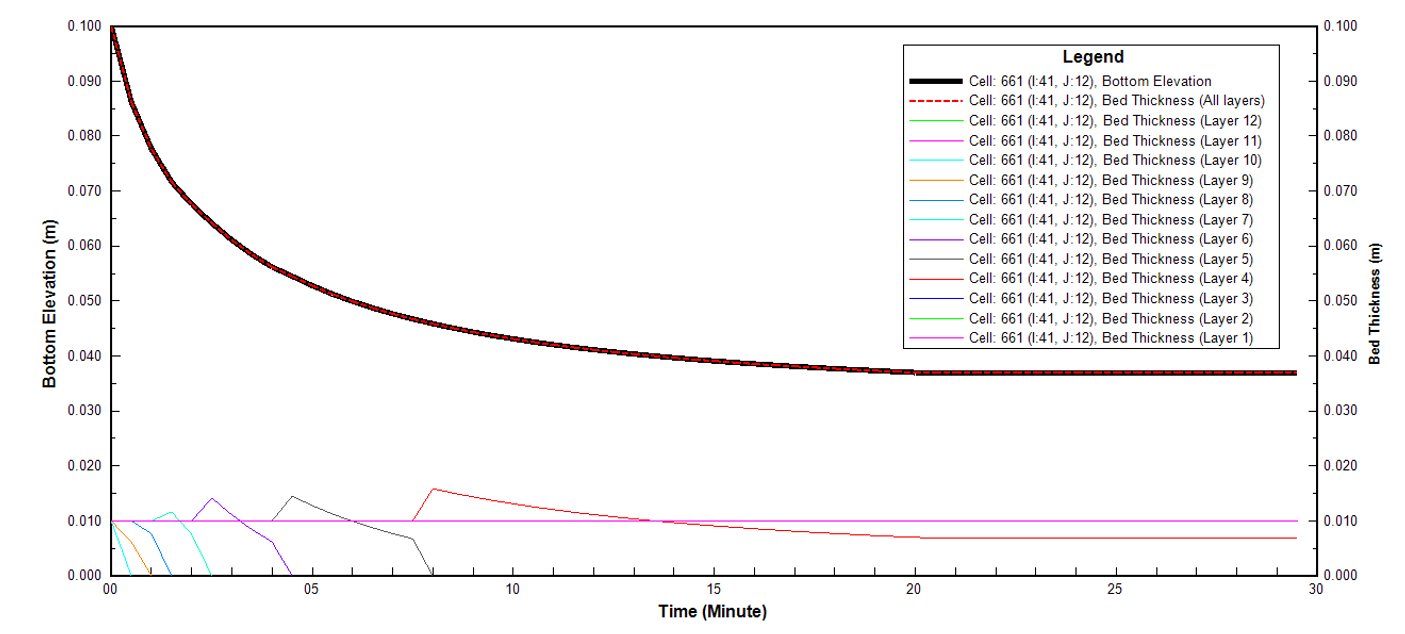

Bed Layer Thickness: Figure 3 presents the changes in bed elevation and sediment bed layer thickness during the simulation at the cell where the maximum scour occurred. The time series plot indicates that the bed elevation matches the total sediment bed thickness during the simulation. Additionally, we can also check how the sediment bed layers behave vertically while the sediment bed is being scoured due to the propeller action.

-

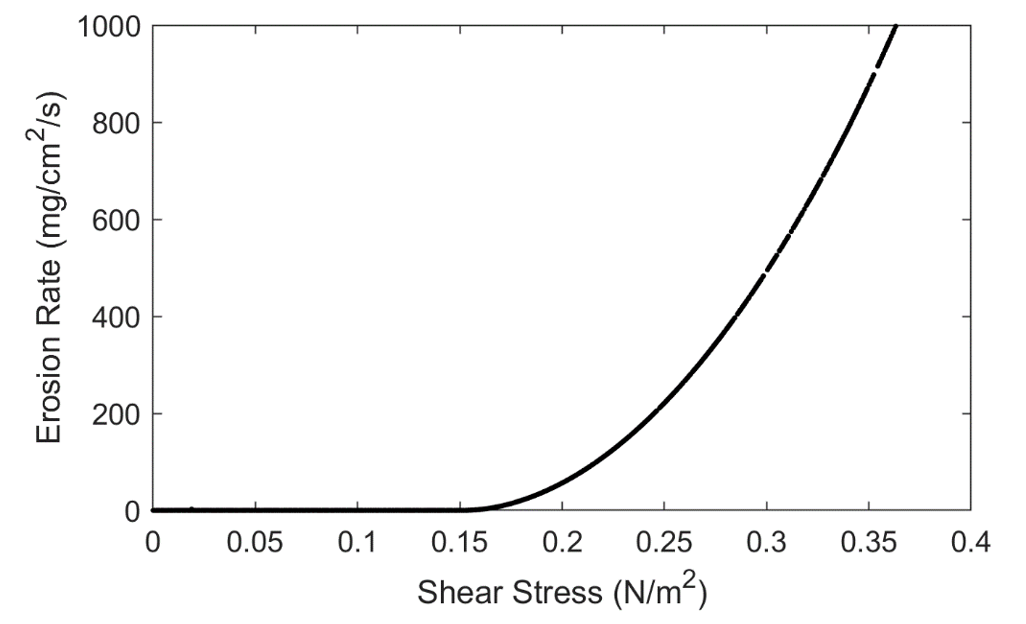

Erosion Rate: EFDC+ computes the propeller-induced velocity field, shear stress, and erosion rates based on an independent Lagrangian sub-grid mesh of each propeller. Figure 4 shows the relationship between the shear stress and erosion rate calculated at a specific time step (t = 5 min), based on the sub-grid points. We can confirm that sediment erosion initiates when the flow shear exceeds 0.154 N/m2, and then the erosion rate increases as the applied shear stress increases. This relationship is consistent with the behaviors suggested by van Rijn’s equations (1984a, 1984b, and 1984c) corresponding to sediment particles with 100 µm diameters.

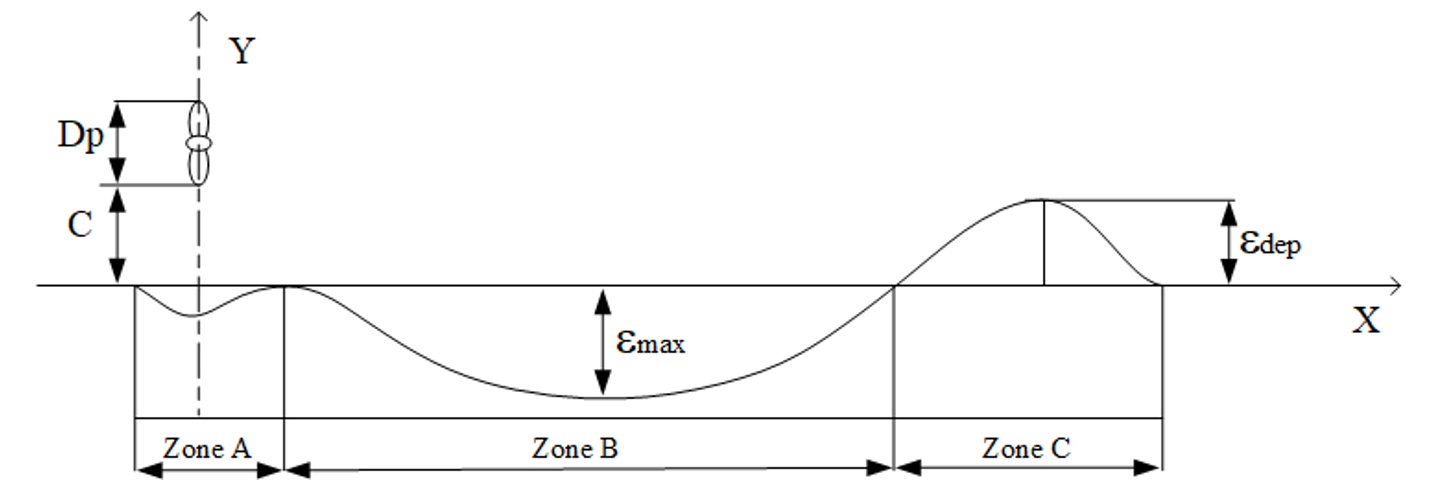

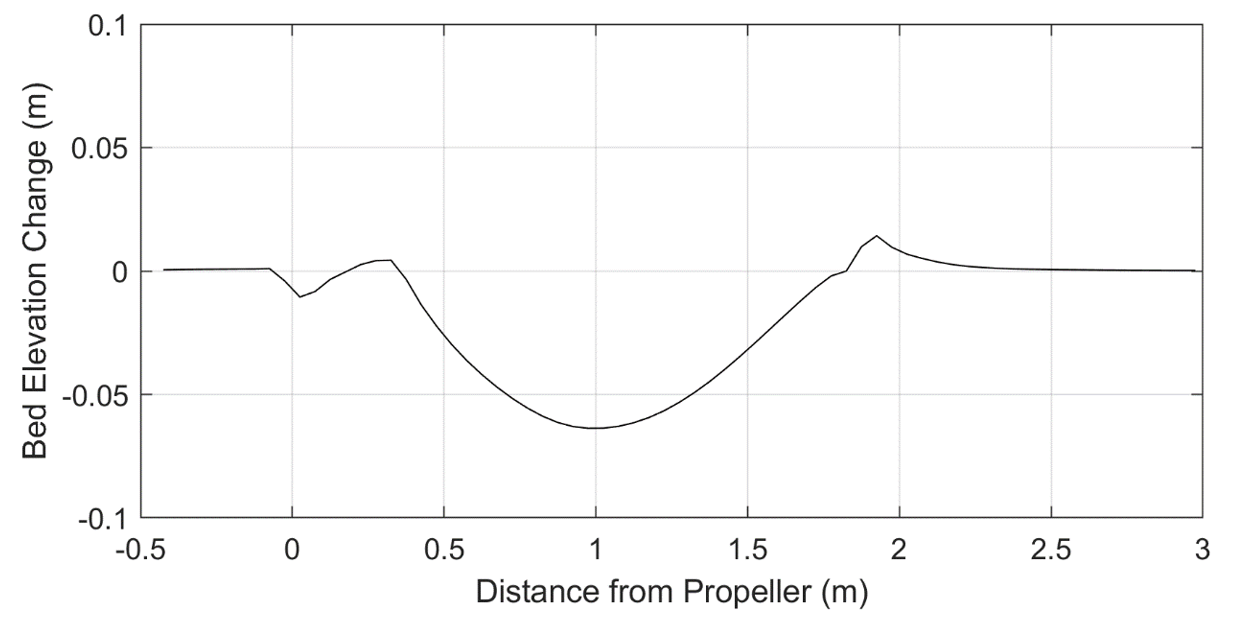

- Scour Depth Profile: Figure 5 illustrates a general concept for a propeller-induced scour profile, which can be divided into a small scour hole below the propeller (zone A), a primary scour hole (zone B), and a deposition dune (zone C). Figure 6 demonstrates that the longitudinal profile of the simulated bed elevation changes align with the propeller axis, and this plot suggests that the model can reasonably reproduce the three indicated zones.

Further Recommendation

The demonstration described above is the basic level of propeller wash module testing; further investigations can be implemented as follows.

If measurement datasets are available, we can evaluate the model performance quantitatively. Specifically, many researchers have conducted flume experiments to suggest empirical equations for propeller-induced scour profiles. We may, therefore, use those published datasets (e.g., maximum scour depth and location of zones A and B, maximum deposition height and location of zone C) to evaluate the model performance. For this analysis, it is essential to build a model simulation setup that corresponds to the given flume experiment conditions. Additionally, several hydrodynamic and sediment transport parameters (which may not be provided in the associated reports) must be defined.

The demonstration should also be conducted using a variety of sediment properties and propeller setups. As to sediment properties, we can examine the model behaviors for other size sediments, mixtures of cohesive and non-cohesive particles, spatially varied bed elevations, and vertically and horizontally varied beds with respect to physical and erosional properties.

For the propeller setups, we can investigate the impacts of propeller features like the number of propellers, the number of propeller blades, propeller diameter, propeller hub diameter, distance between propellers, blade area ratio, pitch ratio, ducted propellers, and thrust coefficient. It is also worth exploring the simulations with different propeller operations, such as propellers at a fixed location with constant power, propellers at fixed location with varying power, moving propellers with constant power, and moving propellers with varying power; such scenarios can more realistically represent vessel movements.

The new Propwash features will be available in EEMS10.3 schedule for release in March 2021. Learn more about user guidance here. To be notified of new developments, sign up for the EEMS newsletter.

Want to give EEMS a try with propwash? You can start by downloading EEMS and activating in the free demo mode and the running our demonstration model. To see these features in action, head over to our YouTube page.